AKS Bright Annealing Furnace

Technical Highlights

Core technology advantages of AKS bright annealing furnace, ensuring exceptional processing quality and energy efficiency performance

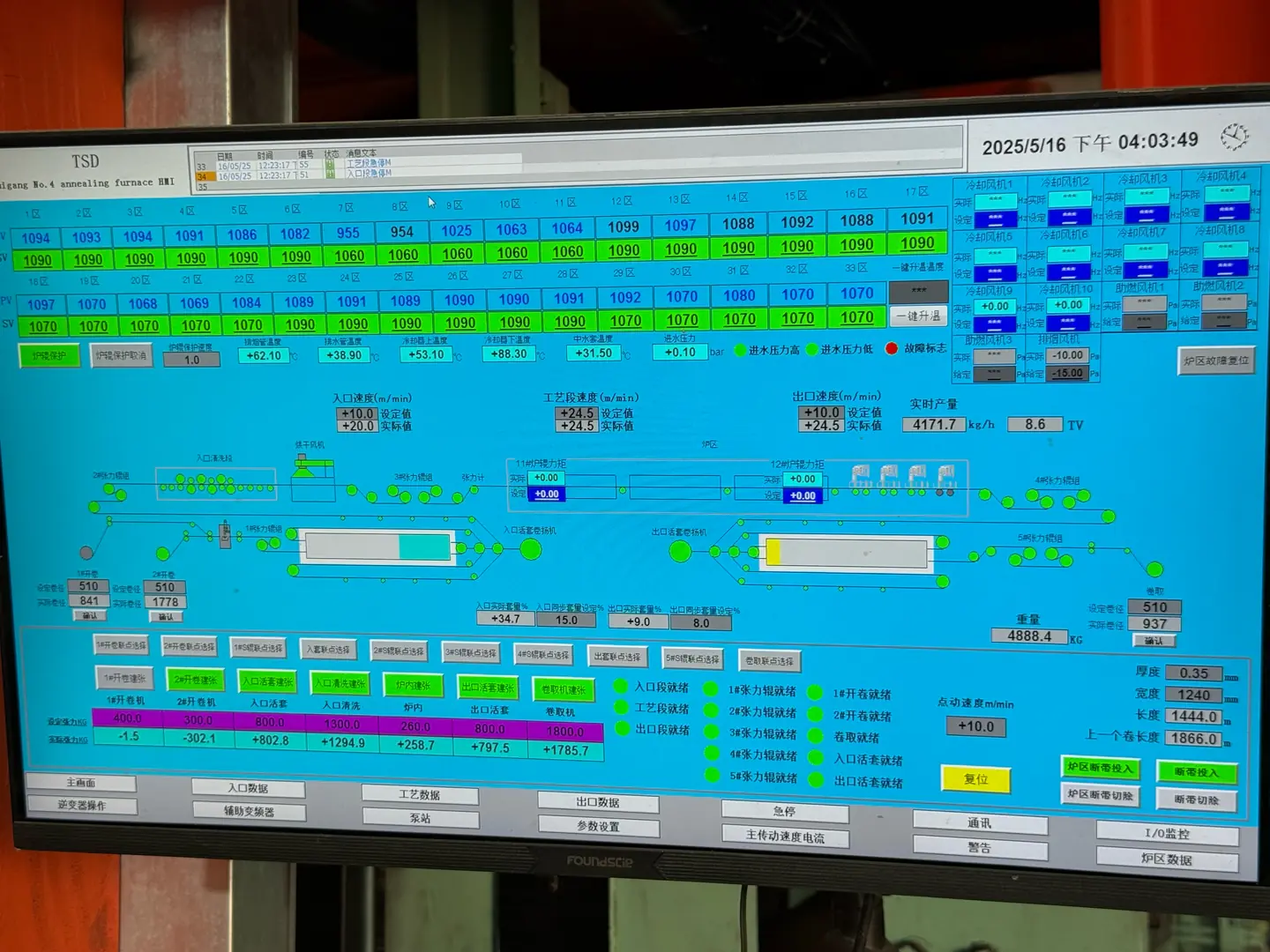

AKS Bright Annealing Furnace Live Monitor

Connecting to live monitor...

High Precision Temperature Control ±2℃

Ensures consistent metal surface brightness, guaranteeing product quality stability and uniformity

Full Protective Atmosphere System

Oxygen content <10 ppm, effectively prevents surface oxidation and improves product surface quality

Real-time Remote Data Monitoring

Monitor furnace temperature, energy consumption, operating speed and other key parameters anytime

Energy-efficient Combustion + Heat Recovery

Energy utilization efficiency improved by 20–40%, significantly reducing operating costs

Modular Structure

Quick installation, easy maintenance, supports flexible customization and rapid deployment

Application Scope

AKS bright annealing furnaces are widely used in multiple metal processing industries, providing precise heat treatment solutions for different sectors

Stainless Steel Strip and Coil Processing

Professional processing of 201, 304 stainless steel strips, achieving 2BA/BA surface quality to meet high-precision processing requirements

Copper/Brass Strip Rolling Mills

Precise control of copper alloy annealing processes, ensuring excellent conductivity and mechanical properties

Aluminum Foil and Strip Manufacturers

Precision heat treatment of lightweight materials, ensuring aluminum ductility and surface quality

Stainless Steel and Alloy Wire Manufacturers

Multi-material compatible design, meeting special annealing process requirements for various alloy wires

Performance Parameters

Precision-engineered specifications for optimal bright annealing performance

Core Specifications

Temperature Precision

Control accuracy

Energy Efficiency

Energy savings vs competitors

Equipment Availability

Uptime guarantee

Engineered for Energy Saving

and Bright Finish

AKS Bright Annealing Furnace features modular construction with high-strength materials for flexible customization. Every aspect reflects our commitment to precision manufacturing and stable operation.

AKS Bright Annealing Furnace

Modular design with customizable length of 12+14+14+14m, accommodating strip width from 850-1550mm

Complete Production Process Showcase

Control System

Siemens PLC + Touch Screen HMI

Heating Zone Details

Natural Gas/LPG Heating

Production Line Operation

Steel Coil Processing Through Furnace

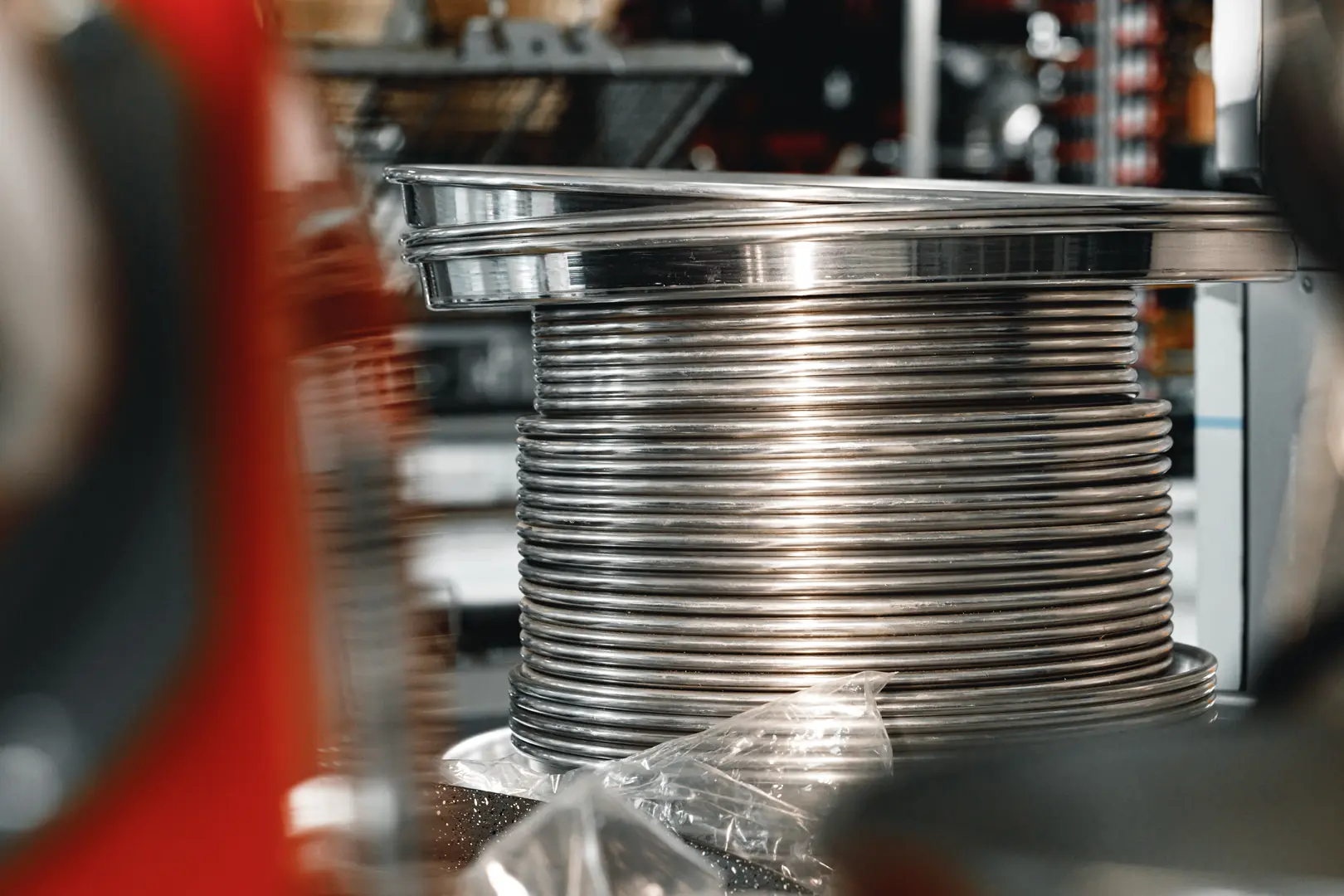

Finished Steel Strip Output

2BA/BA Quality Grade

Trusted by Global Customers

Different metals, different requirements — AKS Bright Annealing Furnaces deliver efficient, energy-saving, and stable performance every time.

Stainless Steel Rolling Mill

Major Stainless Steel Strip Manufacturer

Traditional annealing furnace with high energy consumption, surface yellowing, and insufficient capacity

Aluminum Strip Rolling Mill

Aluminum Strip Processing Company

Traditional equipment with unstable temperature control, uneven strip flatness, and high energy consumption

Precision Steel Strip Manufacturer

High-End Precision Steel Strip Company

Extremely high requirements for product precision and surface quality, traditional furnace with large temperature fluctuations

AKS Bright Annealing Furnaces are widely deployed across Southeast Asia, Middle East, South America and global markets

Professional Engineers Respond Within 24 Hours

Fill out the form and AKS engineers will contact you within 24 hours to provide professional heat treatment solutions

Quick Response Commitment

- Professional engineer response within 24 hours

- Customized heat treatment solutions

- Detailed technical parameter assessment report

Get Professional Consultation

Fill out your requirements and our engineers will provide you with the most suitable bright annealing furnace solution

Contact Us

Fill out the form and AKS engineers will contact you within 24 hours to provide professional heat treatment solutions